Elon's makers are collaborating with the Alamance Makers Guild, STEAM Junction, The Forge and Alamance Community College to produce the face shields that help protect health care workers during the COVID-19 outbreak.

Elon’s Maker Hubs may be closed to the public due to the novel coronavirus, but that hasn’t stopped Elon makers from helping the local community during this uncertain time. As the need for personal protective equipment for health care workers has escalated, local maker spaces in the Triad including Elon’s two Maker Hubs have partnered to create 1,000 face shields for Cone Health.

Senior Instructional Technologist Daniel Reis has been instrumental in this collaboration as he has utilized his connections with other makers in the Triad including the Alamance Makers Guild, STEAM Junction, The Forge and Alamance Community College.

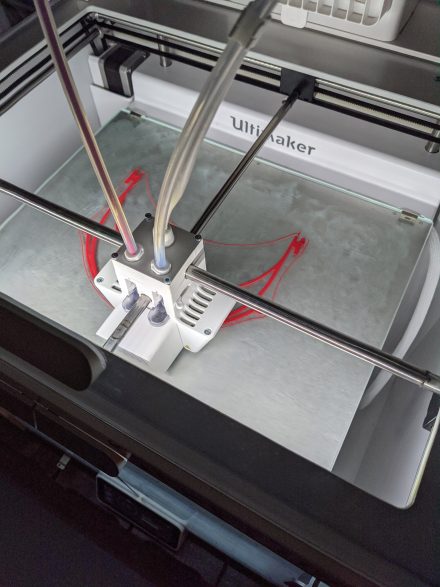

These organizations have come together to make different parts of a National Institutes of Health-approved face shield that is designed to go on top of medical masks worn by health care workers. Although Elon students are not frequenting the Maker Hub since campus has closed, the 3D printers are still hard at work, day and night, printing pieces of the shields.

Elon has 13 printers running almost full time to support the effort. Reis operates four of them and has two students, Sam Jimenez and Anna Altmann, helping operate the other nine. The entire collaborative operation involves about 18 people operating more than 55 3D printers.

Printing the pieces is just one step in the shield production process. Clear plastic sheets are cut and drilled, as is the plastic strip for the back of the shield. The Alamance Makers Guild and STEAM Junction are heading up the cutting and assembly, and are serving as the main contacts between the group and Cone Health.

Reis notes that what is special about this operation is the way each organization is contributing to this operation by utilizing their own strengths of production while building upon new ways to collaborate.

“I’m really proud of the way these organizations have come together around this project,” Reis said. “This was a great opportunity to work together on something. Thanks to our existing connections as makers, we were able to bring everyone together from the Forge, the Makers Guild, and the community college together to support this project.”

During the first week of production since the makers received approval to start on Tuesday, April 7, the group produced 827 total pieces, with 332 of those coming from Elon printers.

But that isn’t all Reis and the Maker Hub have been working on. He has also been printing surgical mask tension release pieces to help alleviate the pain and irritation health workers experience from wearing masks all day. The piece attaches to the elastic straps on the mask and keeps them away from the back of the ears to decrease irritation.

These, too, are in high demand. Reis has already printed nearly 100 of these pieces and is working to produce roughly 100 more. The pieces are being distributed to health care workers in the Triad as well as the Triangle.

“These pieces make it more comfortable for our health care practitioners to wear their surgical masks all day,” Reis said.