A team of student engineers is designing and building an electric racecar to go up against designs from international engineering programs in Formula SAE Electric competitions

Inside Founders Hall’s Clark Prototype Lab, a team of student engineers is paving new ground for Elon: designing and building an electric racecar from scratch.

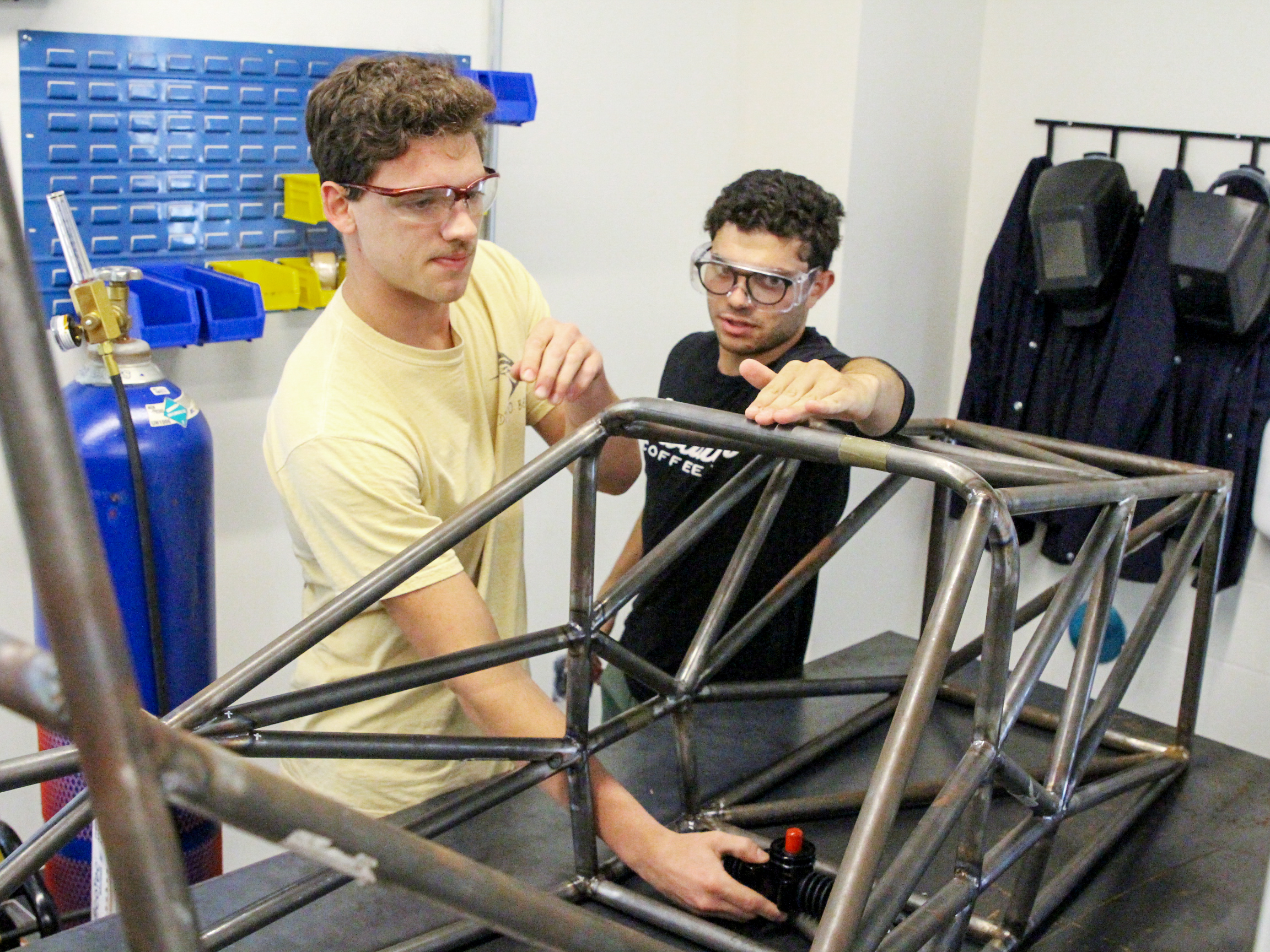

Part by painstaking part, the members of Phoenix Racing — a new Elon engineering program — are machining components, welding the chassis, designing the driver’s interface and the circuitry that will power the motor of a Formula 1 electric car. In the near future, theirs will compete against vehicles created by students in top engineering programs around the world in Formula SAE Electric competitions. Doing so, Phoenix Racing is poised to raise the profile of Elon’s engineering program and enhance future students’ experiences within it.

“I don’t think people realize how big and how cool it is that a group of undergraduates is doing this,” said Nicholas Muller ’24, Phoenix Racing’s co-founder and team principal. “No one on this team knows how to build a car, but we’re doing it anyway. It’s also very meaningful. It matters a lot to us and to the engineering program. It shows what we’re capable of as Elon engineers.”

Phoenix Racing’s ambitious goal is to compete in the June 2024 FSAE Electric competition outside of Detroit. Along the way, they’re raising thousands of dollars from sponsors and partners to design a car that will best last year’s winning time by Georgia Tech: 75 meters in 3.6 seconds. Seventy programs faced off in last year’s FSAE Electric competition, with programs from Carnegie Mellon University, the University of Washington and Virginia Tech placing in the top 10.

Precision matters most, and the cutting-edge equipment in the Innovation Quad’s machine shop and prototype labs made an Elon FSAE team possible.

“These Formula 1-style vehicles drive faster than any car that you can buy,” Muller said. “They accelerate so fast — zero to 60 mph in about 2 seconds — and that’s why they have to be designed so precisely and with high-quality, expensive components: for safety and robustness.”

The electric car project is emblematic of the engineering experience at Elon through its hands-on application of complex technical skills, the collaboration and communication involved in designing and fabricating parts, and its entrepreneurial spirit, said Scott Wolter, associate professor and chair of the Department of Engineering.

“You can visualize making a car, but it’s not until you go about the design and build that you realize all the principles at play and fully learn them,” Wolter said. “I think that’s one of the great things about FSAE competitions: You learn something in class and you put it into practice. There’s nothing better than that kind of experiential learning and that is the environment we promote for our students at Elon.”

FSAE competitions began in 1981, challenging teams of undergraduate and graduate students to conceive, design, fabricate, develop and demonstrate small, lightweight, single-seat vehicles. Entries are judged not just for their speed on the clock, but for innovative designs that control acceleration, efficiency and endurance. Competitive FSAE teams are hallmarks of robust engineering programs, and large institutions can count over 100 members with decades of design and prototype experience inherited from their peers.

Led by Muller, Henry Echt ’24 and Jack O’Donnell ’25, the team is comprised of 18 students from various majors, and advised by Engineering Lab Manager Matthew Banks. Aspects of this first car’s design have been incorporated into the yearlong Senior Projects in Elon Engineering Design (SPEED) course. There, seniors are tackling the car’s subsystem design and build — the human-machine interface and ergonomics behind the wheel — as their final project.

Echt, a computer science and communication design double major, is leading the drivetrain team. After weeks of tinkering, he and Muller sparked the electric motor to life during a February all-nighter.

“I love how I am challenged every day,” Echt said. “The different types of conversations I have help me go into classes with a dynamic perspective.”

Team member Ben Trainum ’24, double majoring in engineering with a computing concentration and computer science, finds the advanced design work invigorating. He’s spent “dozens and dozens” of hours designing the car’s rechargeable battery, along with attaining skills and a level of mastery he wouldn’t have with classes alone.

“These tasks are normally given to graduate-level students. With this team, I’m getting to teach myself and apply high-voltage battery pack design, CNC machining, manual machining, and gaining a far deeper level of mechanical design experience,” Trainum said.

Team members have forged connections with experts in the automotive industry and at other colleges and universities. They constructed the chassis over spring and summer with assistance from the welding program at nearby Alamance Community College.

When they’re not prototyping, they stay busy crafting pitches to potential sponsors and foster channels of communication with business partners. Raising more than $24,000 of the $40,000 they need to be competition ready by May, Phoenix Racing has accumulated an impressive roster of sponsors — among them Sandvik Coromant, Bravo Team, AKG of America, Corvid Technologies, and ACI Automotive and Performance.

There’s still plenty of work left to be completed before the car is competition ready. Members must finish body work, build the power packs and battery management system, complete the electrical system and fabricate the suspension.

But the long hours, late nights and weekends spent in the IQ’s machine shop are paying off ahead of the June 2024 deadline.

“My favorite part of this is who we are,” Echt said. “Everyone’s goal is to build this car, make it to Detroit and show everyone what we can do with a lean, passionate team.”

Those interested in being involved should email Phoenix Racing at PRT@elon.edu.