Class Orientations

3 Ways to Partner with the Maker Hub for Your Class

In-Class Activities

In-Class Activities

Schedule a hands-on Maker Hub experience for your students during your regular class time. See in-class options.

Out-of-Class Assignments

Assign a creative project that students complete independently in the Maker Hub outside of class. See out-of-class examples.

Work Time

Work Time

Use the Maker Hub during class time for students to work on projects. See examples of work time.

Sign Up

Ready to schedule it? Complete the request form to get started. After that, we’ll be in contact with you to confirm everything.

Consultations

Want to discuss your class first? Email the Maker Hub to schedule a consultation with an instructional technologist and explore how we can support your class.

In-Class Activities

This is our most popular option. Bringing your class to the Hub is a great way to introduce them to the free resources and support available for their class assignments and creative exploration. We have 4 options for in-class activities.

Marshmallow Challenge (50 mins)

In the Marshmallow Challenge, students build the tallest structure possible using spaghetti, tape, string, and a marshmallow—encouraging creative thinking, teamwork, and learning through failure.

MacGyver Box Challenge (50 mins)

In the MacGyver Box Challenge, students design and test balloon-powered cars made from random materials, then use insights from their initial test to improve their prototypes.

In both the Marshmallow and MacGyver Box Challenge, students will:

- Engage with Maker Hub tools, spaces, and safety guidelines, and learn about the resources available for creative projects.

- Practice rapid prototyping by quickly building and testing designs using limited materials.

- Collaborate effectively in teams, sharing ideas, assigning tasks, and creatively solving problems together.

- Reflect on teamwork and problem-solving skills, noticing how communication and assumptions impact group success.

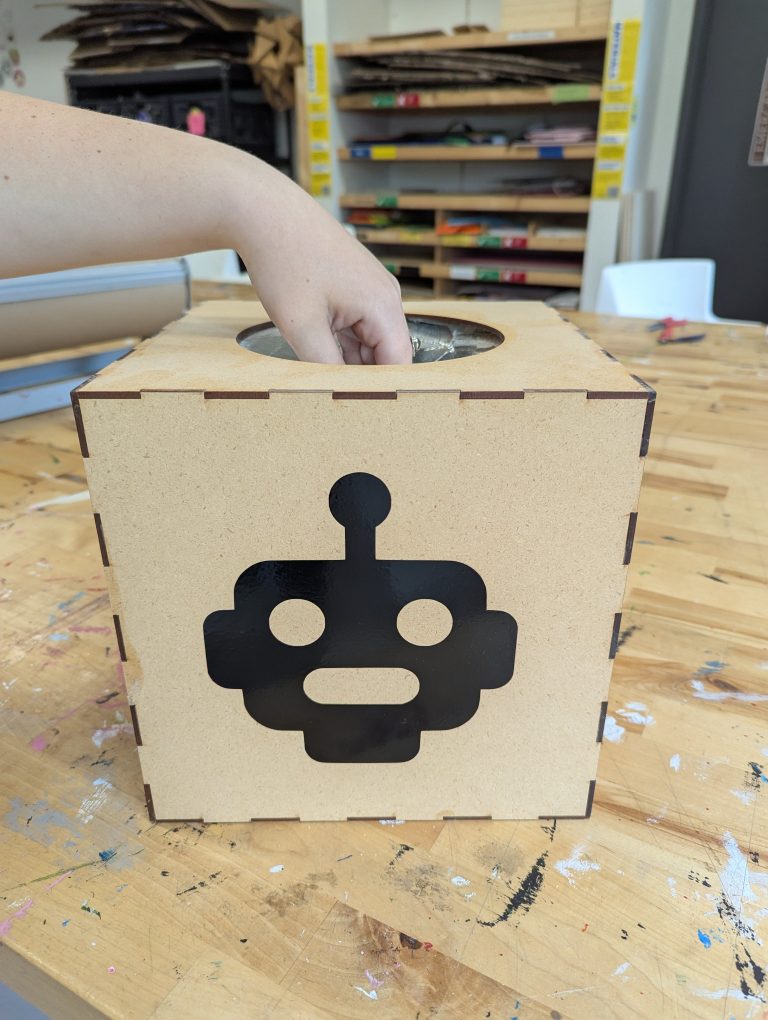

NEW! AI Protobot Challenge (70 mins)

Students use generative AI as a creative partner to create a physical prototype from random materials in the Maker Hub. We can provide the prompts for what the students make or you can provide prompts tailored to your class. This challenge also works without AI.

In this activity, students will:

- Collaborate with AI tools and teammates to generate, refine, and execute creative ideas in response to a design prompt.

- Design and build a low-fidelity prototype using random materials, applying both AI-generated input and human decision-making.

- Critically evaluate the role of AI as a creative partner, recognizing when to adopt, adapt, or challenge its suggestions.

- Engage with Maker Hub tools, spaces, and safety guidelines, and learn about the resources available for creative projects.

Custom In-Class Activities

Custom activities can be tailored to meet your class’s specific learning objectives and needs. They can either expand upon existing Maker Hub activities or introduce something completely new and unique to your course.

Examples of custom in-class activities:

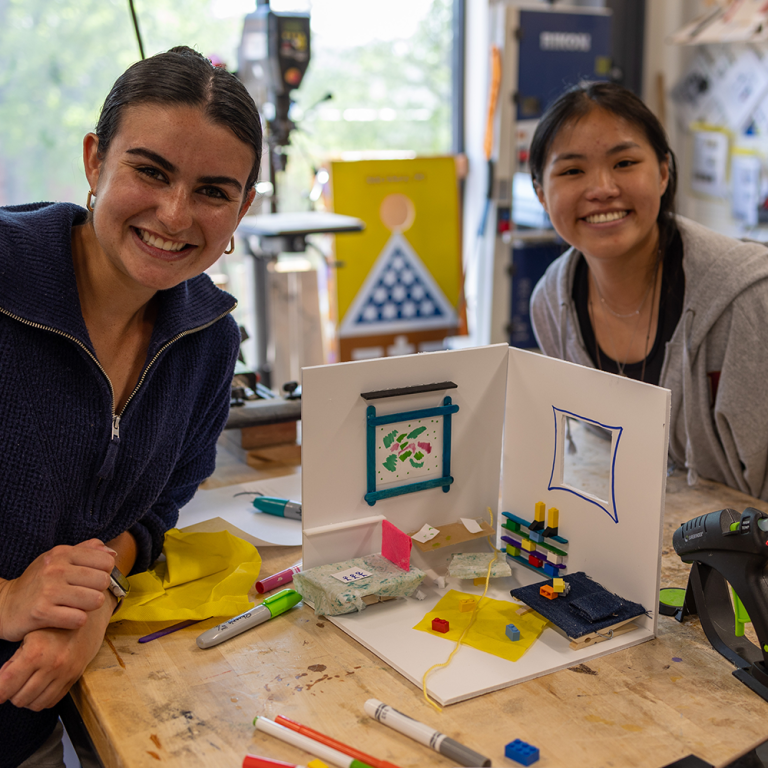

- A Human Services course creating model homes so students better understand their group.

- A History class practicing making chain mail to better understand a process used for hundreds of years.

- A Wellness class where students spent the class creating a representation of what stress looks like to them.

Out-of-Class Assignments

We also work with classes who want students to create something in the Maker Hub but don’t want to spend class time on it.

Examples of out-of-class assignments:

- An accounting class requires students to complete electronics training, build a light-reactive bug, and write a cost analysis for producing the bugs at scale.

- A Latin class researching and 3D-printing historical artifacts for a class gallery, accompanied by a written paper.

- A communications class where students received laser engraver training to create customized projects.

Class Work Time

You can also reserve the Maker Hub so your class can work on assignments or an activity that you’ve created.

Examples of class work time:

- A music production class builds XLR cables using Maker Hub soldering equipment.

- A math class constructs catapults using Maker Hub craft supplies.

- A game design class develops board game prototypes in the Maker Hub.

- An education class designs and leads STEM activities for elementary students.

The prompts and the “Protobot” name were created by Molly Clare Wilson and are used under a Creative Commons license. The Maker Hub expanded on this concept by integrating AI components.